Established in 2016, HESCO is a supplier of equipment, solutions and technical services to customers in the oil and gas, petrochemical, power, steel mills, F&B, water treatment, HVAC...

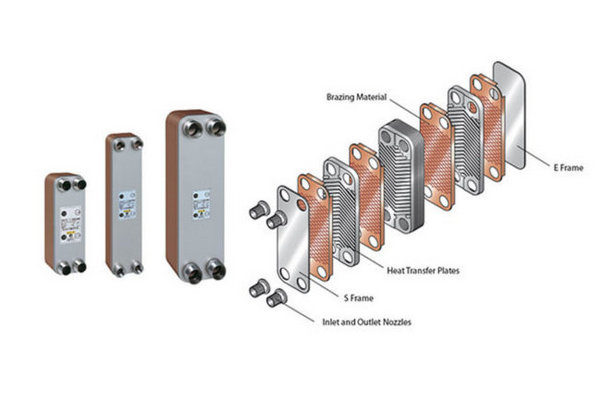

Currently we are the official dealer of the following brands: Heat exchangers and ball valves Hisaka - Japan, Hydraulic equipment, Torishima Pumps - Japan, ESG angle valves, Nakakin pumps